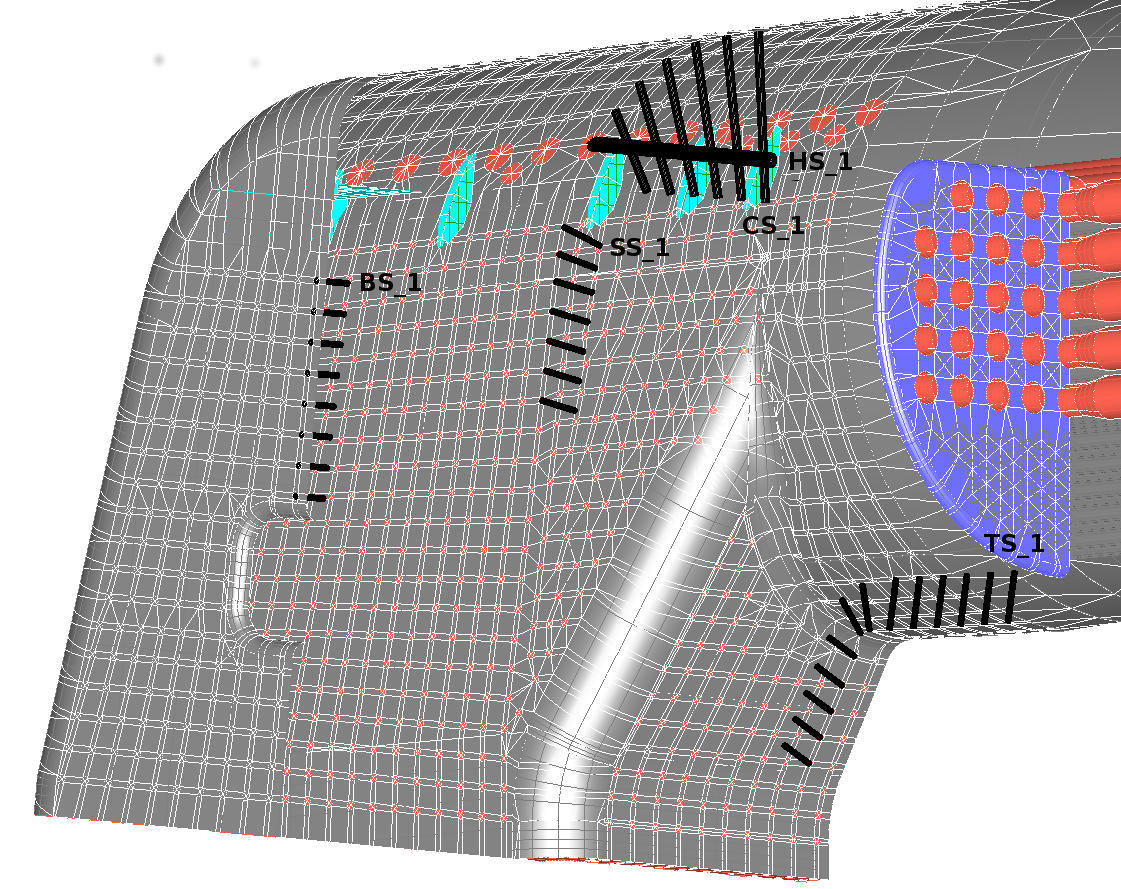

The Rad_ts model adds radial stays ( light blue colour ) in the transition between the throat and combustion chamber to match those originally contained in the 118 boiler model.

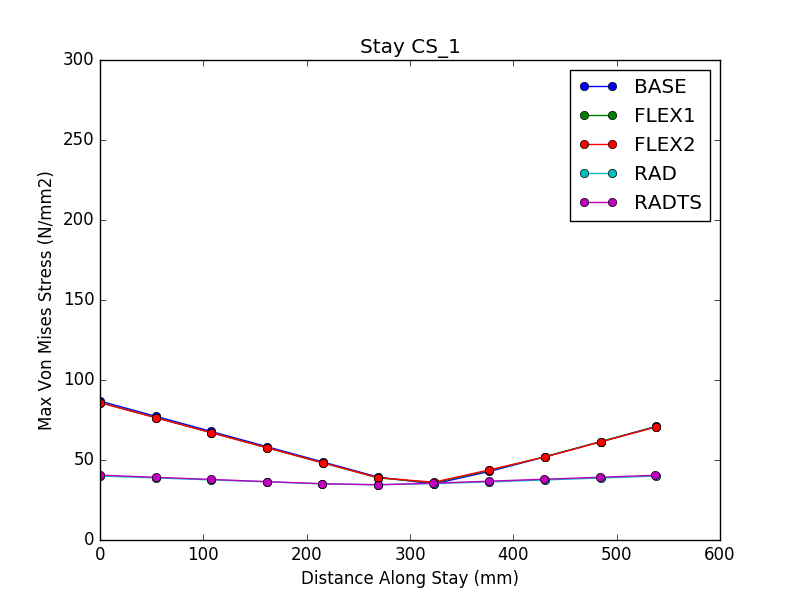

This appears to have a positive effect on all the stays adjacent to that fillet radius but, because it stiffens up the firebox tube plate, it leads to an increase in stress in that area. This is a good example of a change that helps the pressure load distribution but hinders the thermal load distribution. A second variant of the 118 model with throat/combustion transition stays removed shows a commensurate increase in stresses in that area. Two entirely different models show the same effect.

The reduction of stay stresses for TS_1 to TS_7 is very significant especially considering the Rad_ts stays in this area are fixed stays. Stays TS_8 onwards are less encouraging, especially the ones lower down towards the foundation ring. In the model it looks like the lower stays in the boiler are trying to prevent the differential expansion downwards of the lower half of the firebox. This is something that a thicker foundation ring would have been very effective at. I don't know whether there have been problems with the lower stays and consequently whether the FEA model is behaving properly here.

Stiffening the fire box tube plate has increased stresses in both tube plates. There are five variants of the Rad_ts model summarised below that evaluate ways of reducing the fire box tube plate stresses.

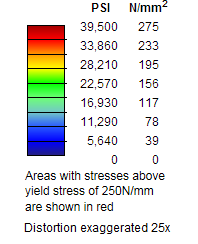

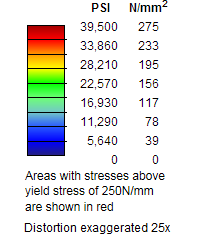

The plot below compares combined thermal and pressure stresses for the flex_2 boiler on the left and the rad_ts model on the right. Clicking on the main image of the five variants will animate a comparison between the original model on the left and the revised model on the right. Click again to stop animation. All the following comparison images can be animated in this way.

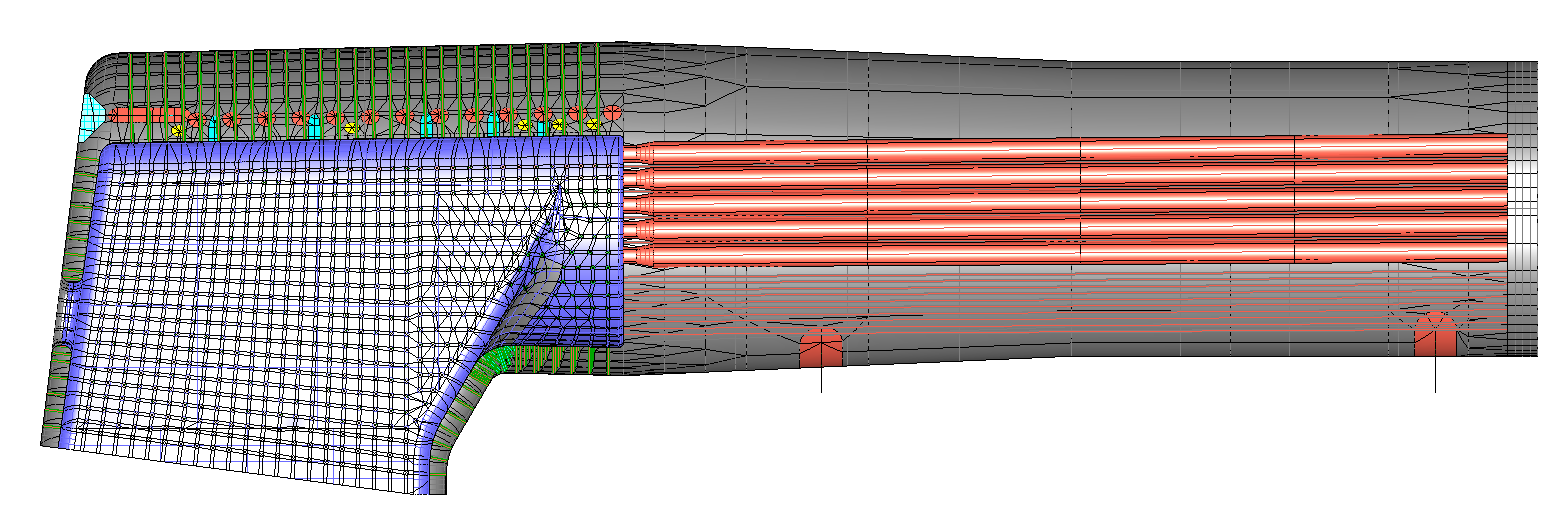

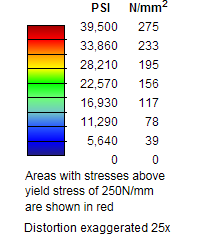

In the model below, all the tubes run parallel to increase the outer margin of the smoke box tubeplate and reduce the triangulation stiffening effect of the original arrangement. Some of the outer small diameter tubes surrounding the superheat tubes have been removed to further increase diaphragm flexibility in both tube plates. The plot on the left is of the Rad_ts model detailed above and the plot on the right of the increased tube plate margin model.

This change reduces firebox tubeplate stresses around the superheat tubes by 20 to 30% but this is at the cost of a reduction of small tube area of 12%. Other methods of increasing tubeplate diaphragm flexibility should be explored.

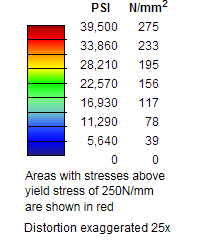

This model decreases the barrel and barrel cone thickness by 2mm to 16mm and 18mm respectively. This reduction may be allowable by using an increased z factor in the barrel strength calculations.

This model combines the changes specified in the two above.

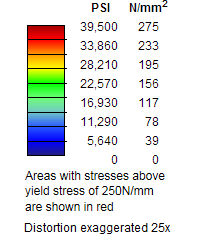

This model also thickens the firebox plate by 2mm.

The cumulative effect of all these changes when coupled with the stays at the combustion/throat intersection leads to a significant reduction in plate and stay stresses throughout the boiler. These observations apply only to the theoretical boiler model and may be impractical but I hope there is some merit in the work undertaken so far.