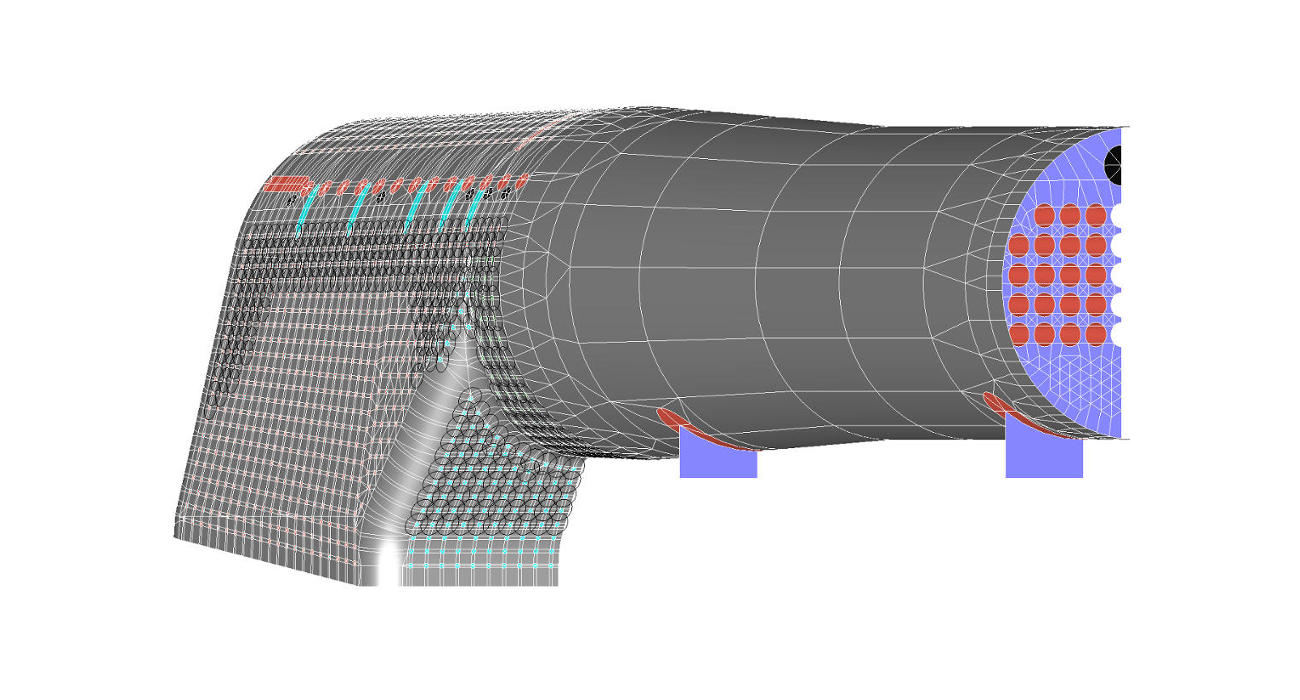

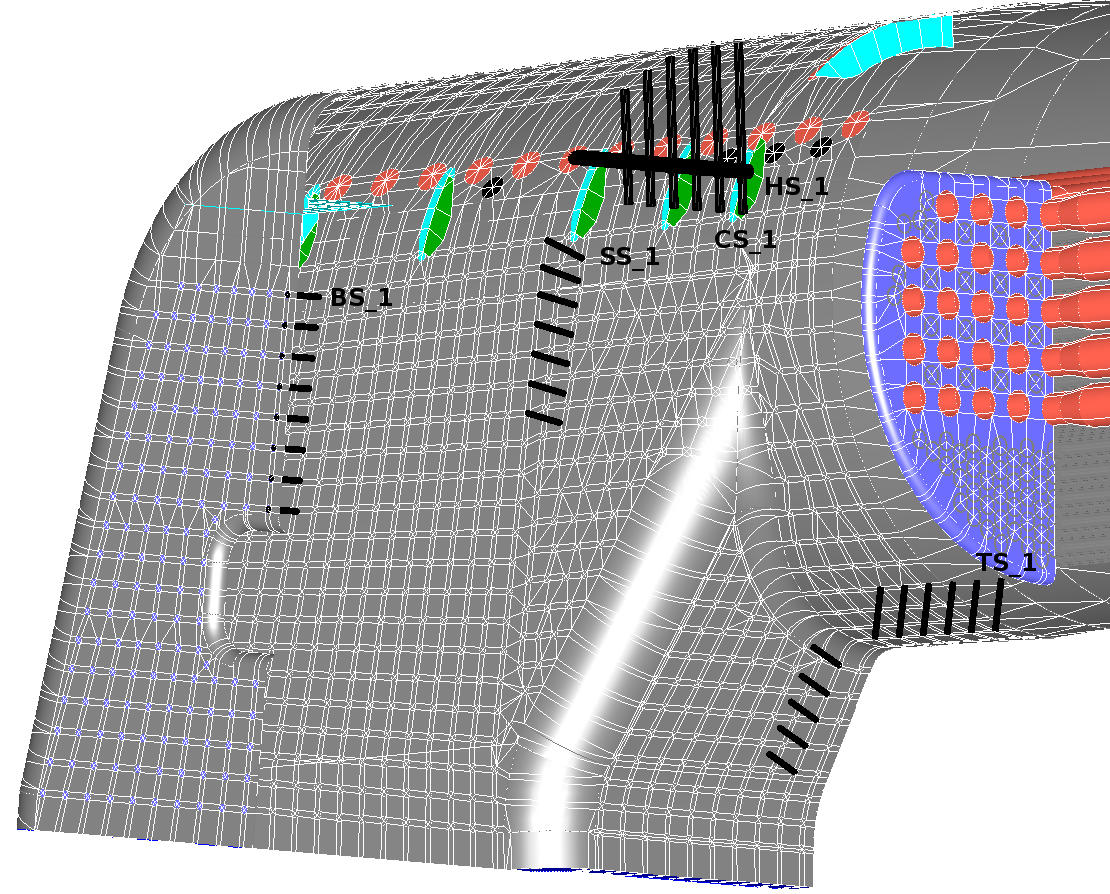

The Flex1 model adds flexible stays to the base model. They are modelled by allowing rotational movement in three dimensions at the outer end of the stay and their positions are highlighted above.

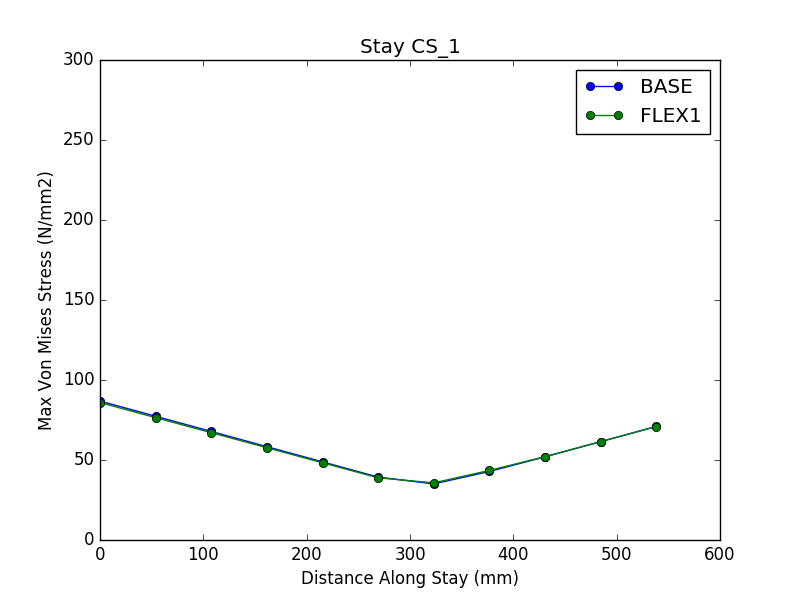

The fringe plots are very similar to the Base model but it can be seen from the individual stay plots below that the removal of bending stress at the outer end of stays helps reduce the stay stress significantly. There is a tendency for the stays below the flexible stays to have higher stresses - this is effectively the flexible stays passing the buck to the stays adjacent to them. There is possibly an argument to say that their inclusion fixes symptoms rather than causes?

Throat stays TS-1 to TS_6 benefit greatly from conversion to flexible form, although only at the outer end of each stay. The model results are likely to be inaccurate here as the stresses are well above the yield point and I don't know if there have been any service issues in this area. ( The introduction of flexible stays here implies that there may have been some? ).

Stay TS7 is the fist stay after the throat/combustion chamber transition and appears to be under very high stress. Stays in this position are likely to be acting in a somewhat similar form to palm stays on a narrow firebox boiler. Stays below TS7 have lower maximum stresses.

The side stay SS_1 benefits from conversion to flexible form but the stays below it are not very highly stressed and so the benefit, in the model, of their conversion is less. Further work shold be undertaken to understand the effects of increased welded foundation ring flexibility when compared to the original riveted form. For example does this reduce thermal effects of the higher stays at the expense of lower stays?

The behaviour of the back head stays appears counter-intuitive but also matches the suspected side stay behaviour, namely an increase in maximum stress in the lower stays.