This page contains many animations and will take some time (e.g. 2 minutes on a 2Mb/s connection) to fully download on slower internet links.

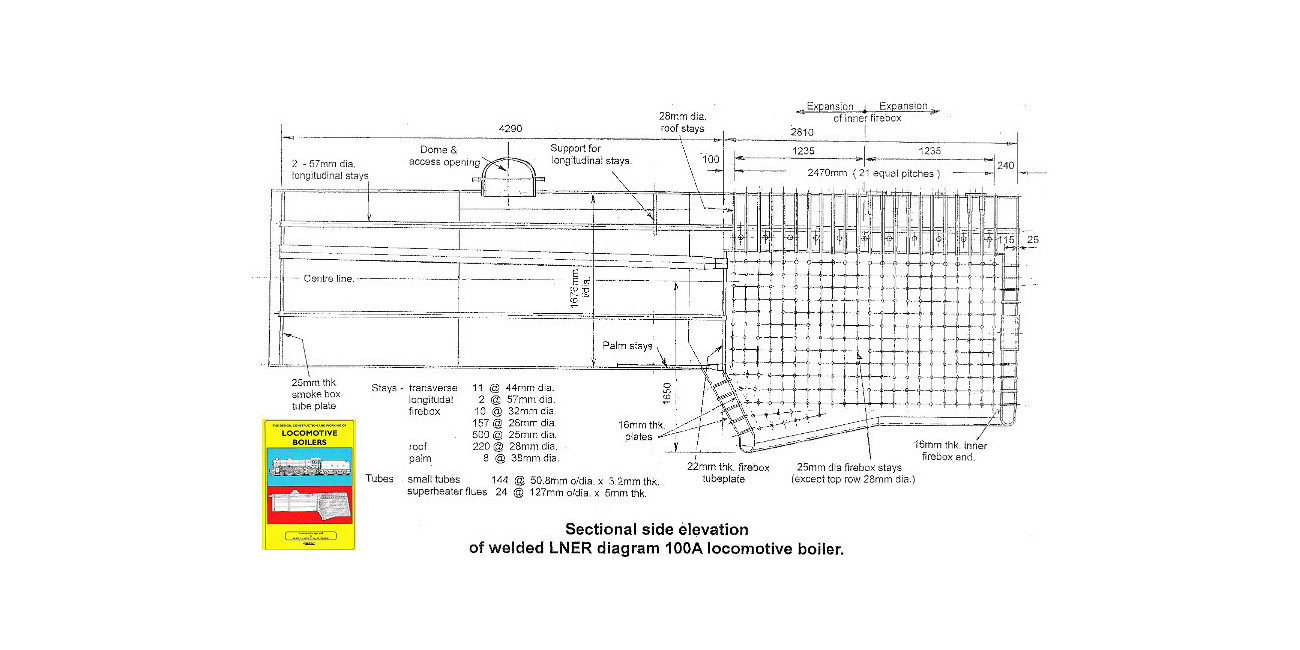

I originally built this model to test how complex a model the FEA system could handle. It's based on a welded re-design of an LNER Diagram 100A boiler from Alan Haig's excellent Locomotive Boilers book. The model has around 12,000 elements and took 75 hours to build.

Model of boiler with a row of horizontal stays above firebox. These stays were added as a modification to the boiler prototype design which showed wrapper distortion and stay failure in adjacent areas.

Whilst their addition reduced wrapper distortion, it still appears to be above the design stress of around 120N/mm2.

Model without row of horizontal stays above firebox as per initial prototype. (the reinforcing patches remain visible in the model but have been reduced in thickness to the same as the rest of the wrapper ) This shows wrapper distortion and likely stay failure in adjacent areas.

As in the smaller marine steam launch boilers the radial pattern provides better support to the fire box crown. Welded construction makes angled crown stays feasible.

Further work needed to reduce stress in throat area ( which is due to my model having a large un-stayed area ) and longitudinal stay arrangement.

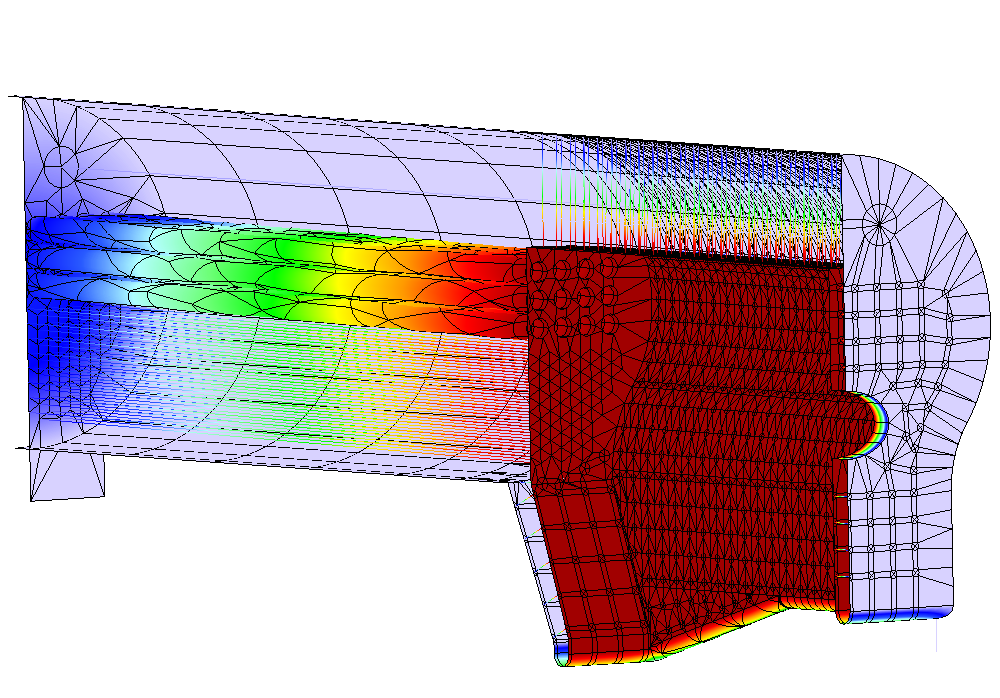

The first stage in trying to simulate stresses due to the firebox being at a higher temperature than the rest of the boiler is to make some assumptions as to the temperatures of each part of the boiler. The structural analysis software needs an input from a thermal analysis to calculate the stresses due to differential expansion.

A thermal analysis is not straight forward for multiple reasons but we could start by assuming that the firebox temperature is constant throughout (of course there will be a temperature gradient across the walls ) and outer wrapper at a lower constant temperature close to the contained steam/water. This simple analysis will provide the information required for a structural analysis. The image below has a 100C difference between the firebox and wrapper. There is no science to this, it was chosen to provide a reasonable difference for a first analysis.